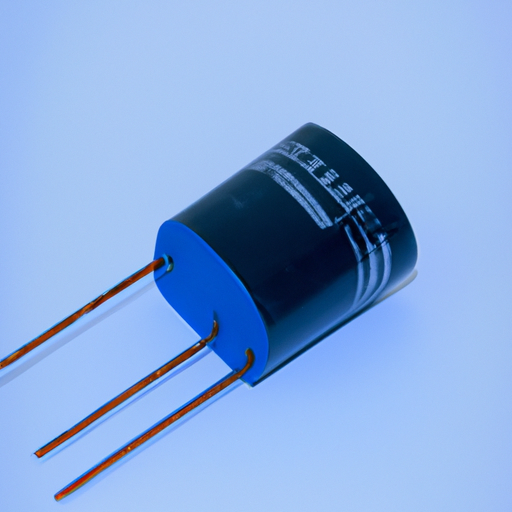

Film capacitors are a type of capacitor that is widely used in various electronic devices and applications. They are known for their high reliability, long lifespan, and excellent performance characteristics. In this article, we will explore what film capacitors are, how they work, their different types, applications, advantages, and disadvantages.

Film capacitors work by storing electrical energy in an electric field between the two metal electrodes. When a voltage is applied across the electrodes, the electric field is established, and energy is stored in the form of an electric field. When the voltage is removed, the energy is released back into the circuit.

There are several different types of film capacitors, each with its own unique characteristics and applications. Some of the most common types include:

1. Polyester film capacitors: These capacitors are known for their low cost and good stability. They are commonly used in consumer electronics, audio equipment, and power supplies.

2. Polypropylene film capacitors: These capacitors have excellent self-healing properties and are known for their high reliability and long lifespan. They are commonly used in high-performance audio equipment, power electronics, and motor drives.

3. Polycarbonate film capacitors: These capacitors have high temperature stability and are suitable for high-frequency applications. They are commonly used in telecommunications equipment, medical devices, and aerospace applications.

4. Metalized film capacitors: These capacitors have a thin metal coating on the film, which provides a higher capacitance density and lower ESR (Equivalent Series Resistance). They are commonly used in high-power applications, such as motor drives, inverters, and power supplies.

Film capacitors have several advantages over other types of capacitors. Some of the key advantages include:

1. High reliability: Film capacitors have a long lifespan and are known for their excellent reliability. They have a low failure rate and can withstand high temperatures and harsh environments.

2. Low ESR: Film capacitors have a low Equivalent Series Resistance (ESR), which means they have low power losses and high efficiency.

3. Self-healing properties: Polypropylene film capacitors have self-healing properties, which means they can recover from small electrical faults without causing a catastrophic failure.

4. High capacitance density: Metalized film capacitors have a high capacitance density, which means they can store a large amount of energy in a small package.

Despite their many advantages, film capacitors also have some disadvantages. Some of the key disadvantages include:

1. Limited voltage ratings: Film capacitors typically have lower voltage ratings compared to other types of capacitors, such as ceramic or electrolytic capacitors.

2. Limited temperature range: Film capacitors have a limited temperature range compared to other types of capacitors, such as ceramic or tantalum capacitors.

3. Size and weight: Film capacitors can be larger and heavier than other types of capacitors, which can be a disadvantage in space-constrained applications.

In conclusion, film capacitors are a versatile and reliable type of capacitor that is widely used in various electronic devices and applications. They offer high reliability, long lifespan, and excellent performance characteristics. Despite some limitations, film capacitors are an essential component in many electronic circuits and play a crucial role in ensuring the proper functioning of electronic devices.